Black & McDonald is an integrated, multi-trade prime contractor with services ranging from construction and planned maintenance agreements, to facilities management and operations. As a result of business growth, Black & McDonald moved 120 employees to a new office in Markham, Ontario.

The new office offered an opportunity to establish a new approach to waste management and a change in office culture. Black & McDonald implemented a centralized waste management system and set a lofty goal of achieving zero waste.

Challenge

To achieve a zero waste office, the Facility Management and Operation’s Energy and Sustainability team decided to implement a centralized recycling program. Rather than having deskside trash and recycling bins, employees would dispose of their waste at convenient stations throughout the building.

Solution

By initiating the centralized recycling program, the employees were tasked with sorting their own waste, thus taking ownership of the waste they generated. They became motivated to make the right choices at the bins to increase diversion rates.

To identify how many recycling containers were needed, the sustainability team reviewed the construction site several times. Carolyn McDonald, Energy and Sustainability Coordinator states “We considered areas where people would be walking regularly to identify the high foot traffic corridors, and planned the container locations accordingly.”

The new recycling, e-waste and confidential paper collection bins were then plotted on floorplans of the building.

The next step was to select a recycling container supplier. The sustainability team partnered with CleanRiver Recycling Solutions stating “We liked CleanRiver’s philosophy and closed loop manufacturing. We hoped to create lasting relationships with responsible vendors.”

The sustainability team considered the type and typical volume of anticipated waste from each facility area, and worked with CleanRiver to select containers with the appropriate capacity, footprint and aesthetics.

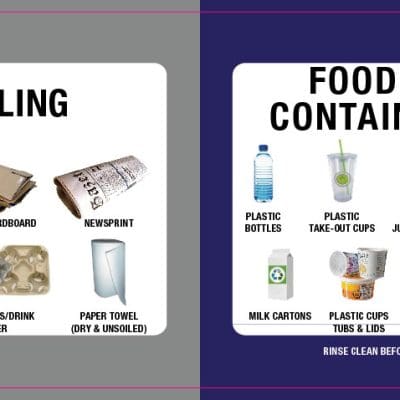

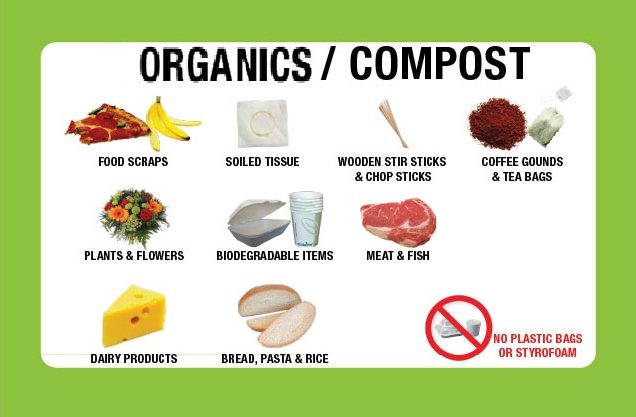

The customized graphics include facility-specific images of waste and text for maximum impact and recognition.Due to the lack of industry standard colors for recycling streams, the sustainability team chose what they felt were the most commonly used colors. The recycling containers have consistent color-coding for the stream openings and graphics: blue for recycling, grey for paper, green for organics and black for landfill waste.

The sustainability team now sends out monthly communications to all employees to inform them of their current diversion rate. The waste hauler generates a report showing the impact their program has on the environment in terms of resources saved. This keeps everyone motivated to achieve their zero waste goal. This report has been fundamental in highlighting the program’s progress and overall impact to the Black & McDonald team.When Black & McDonald employees transitioned to their new office, they were required to participate in an information session. The session covered the new office culture and protocols including Black & McDonald’s focus on sustainability and the new waste management system. Everyone learned how to divert their waste by placing it in the correct stream and make the right choices at recycling stations.

Including the custodial staff was made a priority by the sustainability team. The waste hauler gave a presentation and guidance to the custodial staff for disposing waste effectively in the back-of-house bins; and, the facility manager enabled a simple communication system for the evening and weekend custodial staff to provide feedback or suggestions for the new program.

Impact

3 months after moving into the new office, Black & McDonald achieved its zero waste goal with a diversion rate of 93% and continues to maintain a diversion rate of more than 90%!

To summarize, here’s how Black & McDonald used the 3C Process to achieve their 93% diversion rate:

- Had a dedicated resource to plan and execute the recycling program.

- Baked the recycling program right into the site construction floor plan.

- Made employees responsible for disposing the waste they produce.

- Included the custodial staff in the launch and ongoing monitoring of the recycling program.

- Involved procurement to reduce the amount of waste coming into the facility.

- Launched the program to employees, telling them what goes in each stream.

- Distributed monthly communications re diversion metrics and resources saved.

- Maintained ongoing communication with the custodial team for continued improvement.

- Provided clear graphics and use of color coordination to help people make the right choice.

- Standardized the program with the consistent graphics and colors on all bins in the facility.

- Identified the high foot traffic areas and placed bins accordingly.

- Ensured the right number of bins per department head count.

- Chose the correct capacity and foot print for each location.

- Enabled the waste hauler to do a presentation to the custodial team on how to dispose of the back-of-house waste.

Ongoing Improvements

Black & McDonald’s next goal is to reduce the amount of total waste they generate. Procurement is on board. They are reviewing the type of waste that’s coming into the facility, and working with vendors and suppliers to provide either recyclable or compostable packaging options.

The sustainability team is planning an internal waste audit to measure the levels of contamination in each stream. This will further identify areas for improvement to their recycling program.

Black & McDonald is currently integrating similar waste management programs in the facilities they manage and operate. By collaborating with their clients, Black & McDonald applies simple, tangible and measureable sustainability initiatives into the services they offer.

Congratulations to Black & McDonald on creating such a successful program! To learn how the CleanRiver 3C Process can help you achieve your waste diversion goals call us today at 1-888-646-4246 or email sales@cleanriver.com.